Oaxaca is known as the culinary capital of Mexico.... Mole, Pazole, Tlayudas, Chocolate and Coffee are all important products of this region. But Mezcal, a clear and potent alcohol, is probably Oaxaca’s oldest and most important culinary specialty. Read on to find out why!

Mezcal is made from the Agave, or Maguey, plant. There's hundreds of varieties of agave but mezcal is made from about thirty different varieties which can be found in the wild and cultivated at home. Only nine states in Mexico are certified to manufacture and sell mezcal, otherwise the label can only say "Agave Spirits". In comparison, Tequila is made only from the Blue Agave plant and can be manufactured in five Mexican states.

Since before the Spaniards arrived, the Indigenous of this area were fermenting the pulp from a variety of agave plants, and drinking the fermented juice called Pulque. The Spaniards brought the idea of distillation to the process and the mezcal we know of today was born. Incidentally, this beverage was historically known as Aguardiente, which means "blazing water". Good description.

Over 80% of mezcal is produced in the Mexican state of Oaxaca with the rest being produced in the other eight states. So of course, while I was here, I sampled and "kissed" a lot of varieties and learned about the different plants.

During my time in Oaxaca City, I went on two different factory tours at Valley Oaxaca and El Rey de Matatlan. The Valley Oaxaca Tour was led by our Airbnb host, named Daniel, for the Airbnb guests from our apartment complex. Daniel drove us out of town to meet Sergio, his friend who happens to be a Maestro, or Master, of Mezcal. Sergio started the tour of his factory by taking us out back to his agave plantation.

Depending upon the agave plant, it can take up to 25 years to mature and be ready to harvest. They can be harvested year-round to the discretion of the distiller, but late in the dry season (early-Spring) is best because this is when the plant has concentrated all of its sugars into the piña. As I said, many species can be cultivated, but many others can only successfully propagate in the wild with the help of other plants and animals. These "silvestre", or wild, plants of course are used to produce the more rare and expensive types of mezcal.

Jimadores are professional harvesters of the agave, and they use a special flat disk-shaped hoe named a jima, a machete, or a sickle-shaped tool called a coa to cut out the large "piñas" that form above ground in the center of the plant.

At the factory, the piñas are peeled and cut into quarters ready to be smoked. Workers first line the fire pit with hot lava rocks and wood such as mesquite to make a smokey and aromatic bed of coals. Then they add left-over fiber-waste from previous batches of mezcal to protect the piñas from burning. Finally, they place the pieces of the piñas on top, and cover everything with a giant tarp. They let the piñas smoke for about three days.

When they uncover the pit, they remove the smoked piña pieces, sometimes letting them rest for a few days to further concentrate their sugars.

Next, they take the smoked piña pieces and put them into a shallow concrete pit to be ground by a

400 kilo mill stone, drawn around in a circle by a horse or mule.

After being milled, the stringy wet pulp is transferred into a barrel or vat, often made of North American White Oak. The barrel is covered and the pulp is left to ferment for a few days in hot water, and a few more days in cold water. Sergio on the left, and Daniel on the right are shown here looking into the fermenting barrel.

Once it has been fermented, the juice is called pulque and is a popular refreshing drink. But to make mezcal, they take the pulque and some of the pulp and shovel it into the copper kettle seen here next to Daniel. A fire is built underneath, and the process of distillation begins. To remind you how that works, as the copper kettle gets hot, the alcohol contained in the liquid vaporizes at a faster rate than the water and it sends steam up through the pipe and over into a cooling bath which causes the steam to turn back into a liquid. The final product drips out through a valve at the bottom and the Maestro (the Master Mezcal Distiller) is skilled in differentiating the taste of the "head" of the liquid as the strongest concentration of alcohol and methanol, the "body" of the product, and the "tail" as the weakest alcohol concentration. Mezcal is always distilled twice to maximize the alcohol production, which also maximizes the smokey flavors and purifies the product.

Once the mezcal has been distilled, it is stored in large containers ready to be bottled.

Or, some varieties are stored in oak barrels for one to several years. It’s common for mezcal factories in Oaxaca to buy previously used barrels from Jack Daniels in Lynchburg, Tennessee. Barrel storage gives the mezcal a tawny color and adds depth and variety to its flavors.

Finally, the mezcal is bottled, using the same methods and machinery as a milk bottling plant.

These bottles are waiting to be filled and labeled. Some mezcals are used as the spirit to make cocktails or sweet liquors. These liquors are probably nut and pistachio flavors. Yummy!

Sometimes, the Maestro might add a caterpillar to the bottle before sealing it for storage. This butterfly or moth larvae, is actually a pest of the agave plant and is collected by the grower because of the additional flavor it adds to a bottle of mezcal. I'm not sure if it's a form of just reward for the caterpillar, but I do admit, I liked the flavor of the mezcal with the worm included.

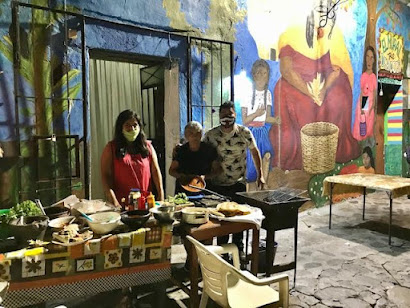

After our informational tour, Sergio and Romina brought us to the tasting room to share their passion with us.

These are the five types of mezcal Sergio produces: Espadín, a commonly cultivated mezcal often branded as "joven" or young, Espadín Perla, which forms an interesting ring of air bubbles in your glass, Tepeztate, Madre Cuish, and Tobalá. These last two varieties were much more smooth to my taste buds.

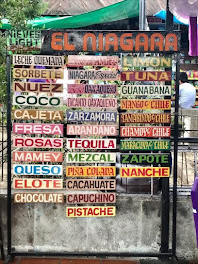

I also loved all the mezcal liqueurs!

On another night, Daniel took us out to Mezcaloteca, a reservation-only

mezcal tasting room where we could sample mezcal from different regions of Mexico.

Carmen taught us all about the historical and current practices of mezcal making. For example, we learned that mezcal used to be fermented in cow hide and distilled in clay pots. Many people still use these traditional practices of making mezcal to keep the historic traditions alive. She also talked about how many organizations around Mexico are trying to preserve the habitat where agave grows and regulate the harvesting practices of wild mezcal, so that certain species of agave are not over-harvested and lost to extinction.

Our Airbnb group: Rob (Canada), Joel (Mexico City), Me, Scott (Oregon)

and Daniel (Oaxaca) all enjoying a few "kisses" of mezcals together.

I, of course, was conducting serious research for this blog!

In the following days, Scott and I also sampled a variety of mezcal cocktails

and ice-creams on several roof-top terraces around Oaxaca City.

It all was serious research!

Mezcal of course isn't cheap, and it's only just beginning to gain popularity in the United States. But, it is a very versatile alcohol and the flavors vary widely between the different plant varieties and processes of distillation and storage. Plus, the syrups and liquors that are also produced just add to its favor. My final analysis, mezcal is really worth a try, again and again.

Salud!